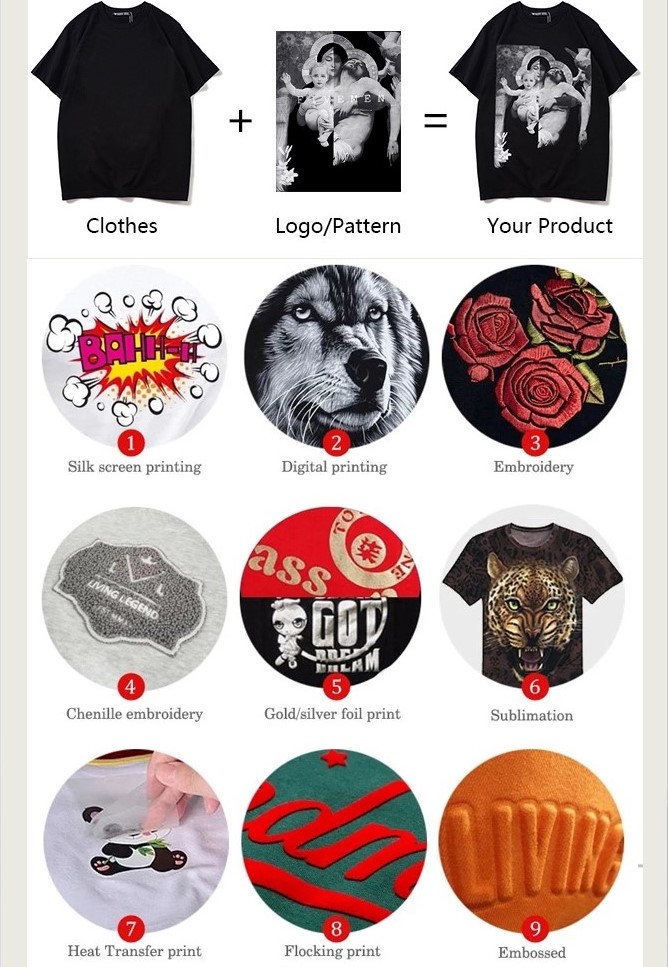

There are many kinds of printing processes for clothing, the following is a detailed introduction of various printing processes for you to choose:

1. Suede foaming (process type: screen printing)

Suede foam is a special printing material that expands at high temperature, and has the same softness and fluffy effect as imitation fur. On the basis of foam printing, the printing has a fur-like effect. The soft hand feels so that environmentalists who like fur can’t put it down. The slurry is mainly heated to form bubbles to make the surface uneven and have a suede effect visually.

Advantages: soft hand feeling, with suede effect visually

Disadvantages: the color of the process pattern is slightly darker

Suitable: suitable for sweaters, baseball uniforms

2. Silk-screen flocking (process type: silk-screen printing)

First silk-print the pattern, then attach a whole piece of colored fluff to the pattern, tear it off after high-temperature heat pressing, which is suitable for detailed and irregular patterns. The three-dimensional effect is strong, and the pattern is realistic.

Advantages: soft touch, plump plush, high-end printing element effect

Disadvantages: for the time being, only single-color flocking is supported, not color interleaving

Suitable: Suitable for cotton T-shirt, supports 30 colors

3. Fluorescent glue Q hot stamping (process type: heat transfer)

A print made of high-elastic PU material. Compared with traditional prints, the color is more vivid and the hand feels softer.

Advantages: comfortable hand feel, the edges of the laser-cut printing are more neat, and the color saturation is high

Disadvantages: The current process supports white, silver, red, orange, blue, black, green, transparent, rose red, burgundy, bright yellow and khaki

Suitable: suitable for simple pattern and LOGO printing

4. 3D thick plate (process type: screen printing)

T company’s thick plate printing uses water-based thick plates, plus high-mesh, high-tension screen printing. Through repeated printing, the thickness of the printing is increased, and the edges and corners are distinct, which is more three-dimensional than the traditional rounded thick plates.

Advantages: sharp edges and corners, more three-dimensional than the traditional thick plate with rounded corners

Disadvantages: The pattern lines need to be larger than 2mm, otherwise the pattern may be distorted after intensive washing methods such as washing and drying.

Suitable: Used for all kinds of knitted fabrics, supports all colors

5. Super thick plate (process type: heat transfer)

The use of ultra-thick three-dimensional 3D thick plates, which are thicker than conventional silk-screened thick plates, and laser cut with skin-feel PU material, the patterns are neat and beautiful, and more three-dimensional than traditional thick plates with rounded corners.

Advantages: use skin-feel material, soft touch, laser cutting, neat edges

Disadvantages: only support black and white, pattern lines need to be greater than 2mm

Suitable for: Letter LOGO printing and neat and simple printing patterns

6. Luminous (process type: screen printing)

Use precious rare earth materials to make high-mesh luminous powder and mix it with highly transparent printing ink. The light-emitting principle is to store light energy in a light environment, and release light energy in the form of short waves in the dark to form a self-luminous effect.

Advantages: it emits light in low light, giving people a special visual effect. T company uses light-storing materials that are harmless to the human body and the environment, which is healthy and safe.

Disadvantages: currently supports 5 different colors of green, sky blue, orange, pink and purple, of which green has the best effect

Suitable: Most suitable for casual wear and children’s wear

7. Reflective (process type: silk screen printing)

Reflective powder produced by ND≥2.2 3M is used. It is made of glass microbead powder. When light is irradiated, it is concentrated on a special reflective layer at the focus of the microbead due to high refraction. The reflective layer reflects the light through the transparent microbeads and re-reflects the light to the vicinity of the light source, resulting in a very bright Reflected light.

Advantages: soft hand feel, anti-oxidation and full of coolness

Disadvantages: only suitable for dark bottom shirts

Suitable: suitable for the requirement that the printing needs to be eye-catching enough, the reflective coating is transparent, any color can be used, the gray pattern has the best reflective effect and the strongest reflection

8, 3M reflective film (process type: heat transfer)

The machine is sprayed with 3M reflective film, laser cutting and engraving, and the reflective effect is strong. Smooth and fine coating

Advantages: Compared with the traditional silk screen reflective, 3M reflective film is sprayed by machine, the reflective surface is smoother, and the reflective effect is better.

Disadvantages: only supports gray

Suitable for: Letter LOGO printing and neat and simple printing patterns

9. Fluorescence (process type: screen printing)

It is a functional luminescent pigment that absorbs a certain form of energy when irradiated by external light (including ultraviolet light), thereby exciting photons, generating fluorescence of different hues, and forming bright and bright colors.

Advantages: dazzling colors, but also comfortable and soft to wear

Disadvantages: The pattern can only be made in 6 colors, namely: yellow, green, purple, orange, rose, pink

Suitable: used to present special fluorescent colors

10. Pearlescent (process type: screen printing)

Using pearl white with pearl luster and pearl paste containing pearl powder as raw materials, it retains its characteristics after being fused with the color-adjusting pigments, making the print appear pearl-like luster.

Advantages: special texture with pearl luster, acid and high temperature resistance, high fastness

Disadvantages: not suitable for large-area printing, easy to absorb fine dust in the air

Suitable: not limited by style and color, but the color of the bottom shirt and the pattern needs to be in contrast

11. Brushed hot silver (process type: heat transfer)

On the silver PU heat transfer film, there is a metal brushed texture. The printing not only has metallic luster, but also looks more textured.

Advantages: The metal brushed lines are shown on the printing, which makes the printing not only metallic luster, but also more textured

Disadvantages: The process only supports silver

Suitable: Suitable for LOGO printing

12. Silk screen bronzing/silvering (process type: screen printing)

Using golden ratio formula, after grinding and high-density screening, it presents gold/silver printing with metallic texture. Compared with the traditional electroplating film bronzing/silver, the luster and beauty of the printing are more durable, the washing is firmer, and the texture is better.

Advantages: metallic gold/silver printing, the gloss of the printing is more beautiful and lasting, and the washing is firmer

Disadvantages: The pattern color is only gold/silver

Suitable for: logo printing

13. Laser silver (process type: heat transfer)

The printing technology of silk-printing laser ink on PU material, using laser to cut, the printing can see rainbow-like colorful reflection gloss under normal visual angle change

Advantages: PU material, anti-wrinkle, anti-oxidation, more durable than traditional laser silver, laser cutting, neat edges

Disadvantages: only supports silver

Suitable for: Letter LOGO printing and neat and simple printing patterns

14. Colorful reflective (process type: heat transfer)

A process that uses the principle of light reflection. Under normal conditions, the printing is gray, and in a dim environment, colorful light will be reflected under the light. The printing can show different colorful effects from different angles.

Advantages: the printing is gray under normal conditions, and it will reflect colorful light under the irradiation of light. The printing can show different colorful effects from different angles.

Disadvantages: suitable for dark bottom shirts

Suitable: The reflective coating is transparent and can be used in any color; the gray pattern has the best reflective effect and the strongest reflection